MODEL MAKING

Jewelry manufacturing begins with the creation of a model, which can be done in two primary ways:

By Hand

Skilled cratismen carve designs out of wax or assemble various metal

elements to create a master model. This traditional method relies on the

artisans' expertise to bring intricate designs to life.

By Computer (CAD/CAM)

Modern jewelry design utilizes Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) programs. These technologies allow designers to

create highly detailed images and models with precision.

MOLD MAKING AND CASTING

Once the master model is complete, a mold is created to enable the

reproduction of the design in any metal.

1. Wax Injection: Hot wax is injected into the mold under pressure. Once cooled, the wax model is removed and used as a casting model.

2. Wax Tree Formation: Multiple wax models are grouped together on a wax tree, allowing several pieces to be cast simultaneously in the same metal and color.

3. Plaster Molding: The wax tree is placed in a form, which is then filled with plaster. The form is baked overnight, melting away the wax and leaving empty cavities in the shape of the jewelry.

4. Metal Casting: Metal is heated to extreme temperatures until it becomes liquid and then vacuumed into the plaster form, filling the cavities leti by the melted wax.

JEWELRY MAKING

When a ring style is ordered, various metal components are prepared according to the ring's

specifications. These components are then assembled and adjusted to fit the desired center stone

and finger size.

1. Assembly: Metal parts are soldered or laser-welded together. Platinum, due to its high melting point, is always welded using a laser.

2. Polishing Stages: The assembled rings undergo multiple polishing stages to prepare them for stone settng.

3. Stone Selection: Diamonds and gemstones are selected with precision, ensuring they meet the style's exact specifications in color, clarity, and cut.

4. Stone Settng: Using special drill heads shaped like the diamonds, bearings are cut into the metal. Each stone is set into its bearing and secured by the surrounding metal. Various methods are used to secure stones, depending on the design.

POLISHING AND FINISHING

The final steps in jewelry making ensure the piece is polished and finished to perfection.

1. Buffing and Polishing: Using different sized and shaped buffs and brushes, every part of the jewelry is polished, from the inside to underneath the gallery.

2. Lapping: This final polishing step ensures a smooth, high-quality finish.

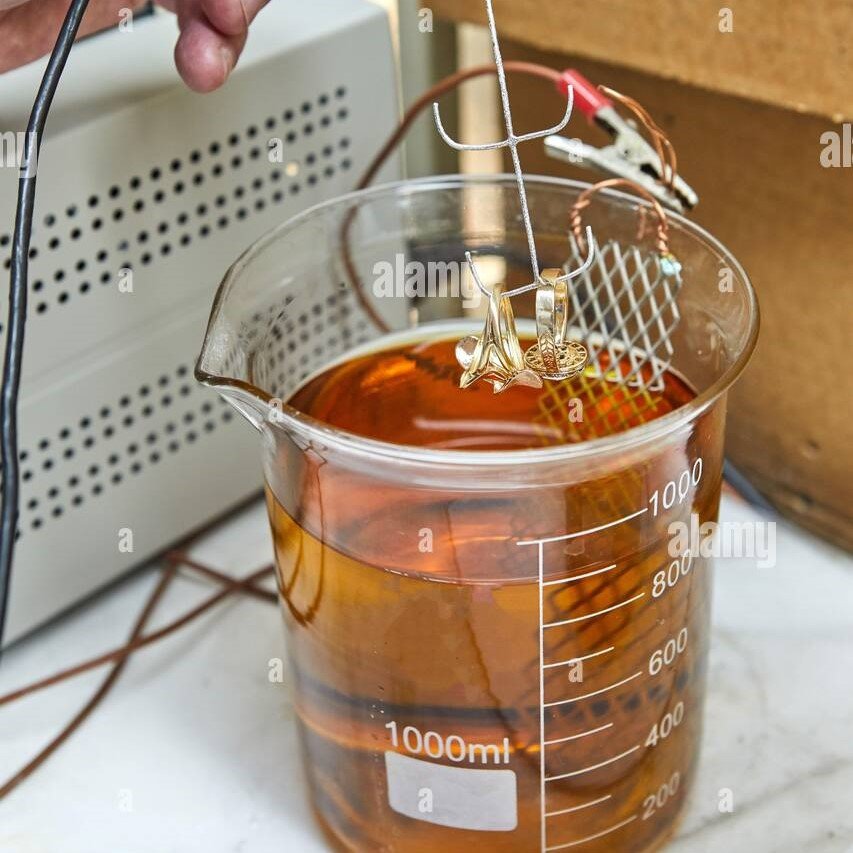

3. Plating: Since white gold is not naturally pure white, it requires plating. The jewelry is plated by attaching electrodes and dipping it in a rhodium solution, giving it a bright, white finish.

At Videh, we blend traditional cratismanship with cuttng-edge technology to create exquisite jewelry pieces that reflect your unique style and love.